Mathews Archery began in 1992 when Matt McPherson created the company based on his first compound bow with Solocam technology. But the seeds to one of the industry’s most successful archery companies began many years earlier thanks to McPherson’s passion.

McPherson has been building bows for more than 50 years. He built his first stick bow when he was 10 years old and his first compound bow three years later. He couldn’t afford to buy one. Innovation and determination guided him, along with a willing shop teacher in school who allowed him to create a bow. Although McPherson didn’t know it at the time, his life’s trajectory was set.

After founding Mathews Archery, McPherson was determined to maintain control over every aspect of the building process. Mathews sources the best materials and micromanages the manufacturing process to deliver innovation, high-quality and craftsmanship recognized by hunters and competitive shooters.

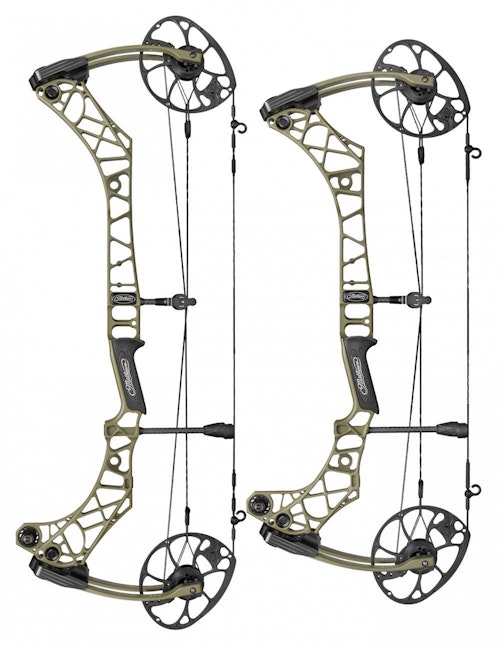

We talked with Caleb Parry, communications manager for Mathews Archery, about the company and its new flagship bow, the VXR, along with the Switchweight module system and new Silent Connect System.

HR: Thanks for taking some time to talk with us. Sounds like the new VXR has generated good response. What are you hearing on feedback and demand?

CP: Despite the factory being shut down for almost two months, we’re having a great year with the VXR. Right out of the gate, people were really excited about the overall shooting experience the VXR provides. There is zero hand shock, it’s deadly quiet and extremely stable.

Our patented Switchweight module technology, which was carried over (from 2019) has also continued to do well. Dealers really got behind Switchweight for its versatility and ease of use. The system allows them to set up a demo bow specific to any customer that walks through their door within minutes. That versatility also carries over for our customers. Say a hunter goes out West for elk and shoots 75 pounds, but he’ll be hunting whitetails in the Midwest late-season when it’s much colder. He can throw on 60-pound Switchweight modules with just a change of four quick screws and he’s ready to go.

HR: The new Silent Connect System looks interesting. How did that come about?

CP: One of our product engineers, Brandon, who works with Matt (McPherson) came up with the idea and used it during his 2019 hunting season. It’s a simple but effective system in the field. We have two complementary accessories that go along with the SCS System — a bow rope and sling. The bow rope orients your bow parallel to the tree so you can easily pull it up without snagging limbs or brush. It has no metal or plastic components, so slipping it on and off your bow in the dark is quick and quiet. We partnered with Mystery Ranch on the sling. It’s made of Cordura for durability, is extremely adjustable and has a non-slip pad so it won’t slide off your shoulder.

HR: Along with Mathews, you have Mission Crossbows, Mission Archery, Genesis Bows and Zebra Bowstrings. From youth to veteran, it seems everything is covered.

CP: Yes, our goal has always been to grow the sport of archery, and all of our companies do just that. Each one of our brands has a specific purpose and fills a void or opportunity to do it better, in the market.

HR: The “Start Your Build” feature allows people to build and customize their bow. How popular is that?

CP: We started to raise awareness about our Bow Builder platform a couple of years ago, and it continues to grow in popularity. Our Bow Builder is one of a kind and allows customers to put their own personal spin on any of our bows.

HR: What’s the most popular color or combination? Anything you guys see more regularly than anything else?

CP: The fluorescent and neon colors seem to be the most popular. It’s not uncommon to go through final assembly and say “whoa” with some of the color combinations, but that’s what’s cool about it — no two bows are the same.

HR: Was the manufacturing plant kept up during the shutdown?

CP: We temporarily shut down for the health and safety of our employees, customers and community. During that time, we had a skeleton crew making sure all of the machines were ready to go when our doors opened back up.

HR: With the impact of the coronavirus and popularity of the VXR, will dealers and consumers see new bows in autumn? Or will the VXR be it for the year?

CP: We will have new products, yes. Matt and our engineers have been hard at it throughout this pandemic. But we’re also excited about finishing the year strongly with the VXR. It’s been solid for us, and we hope the momentum continues.

HR: What’s your favorite bowhunting memory?

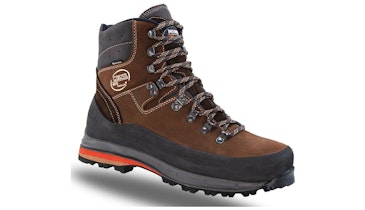

CP: I’d have to say it was my first archery bull in Colorado five years ago. I was fortunate enough to harvest a solid 5-by-5 on an OTC backcountry hunt. My buddy JT and I struggled but stayed persistent, and it finally came together on the last day. I’ll never forget the bull coming in and watching my arrow find its mark. It’s an emotional roller coaster that I’ll never forget.