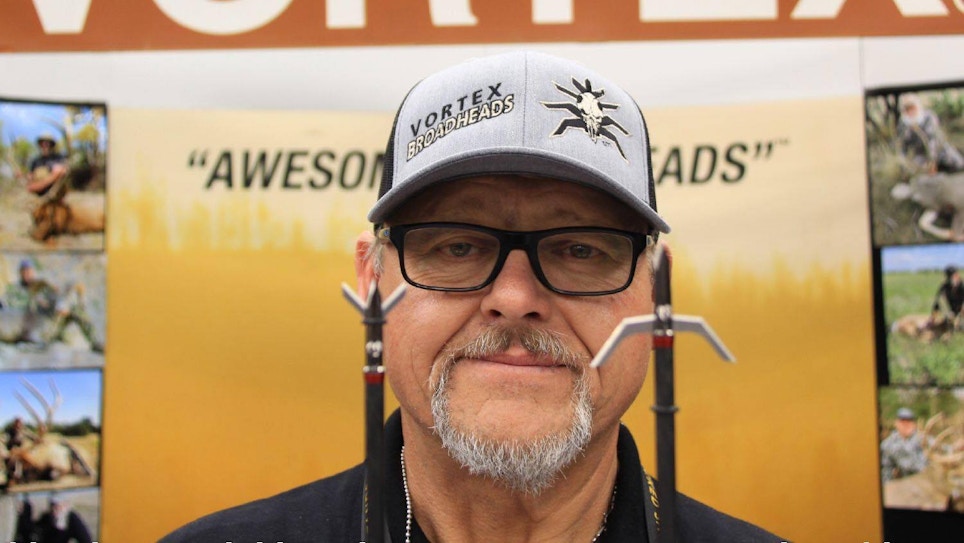

Rodney Ward, one of three brothers who own Vortex Broadheads, at the company’s booth during the 2023 ATA Show. The head shown is an American Archer Vortex.

Vortex Broadheads is based in Arizona and has had a successful run for more than 3 decades with a straightforward business plan: keep things simple and if it works, don’t mess with it.

Founded by Dennis Ward in 1988, the company took its roots in his home garage. A marginal shot on an elk caused Ward to think about his gear, especially the broadhead. Being the first thing that contacted an animal and caused, hopefully, mortal damage, Ward wanted something that was big, strong, tough and effective. He created Vortex Broadheads and took them to market 2 years later. Since then the company has ridden the highs and lows of the archery industry with a loyal following and much success in the field.

Ward died last autumn after battling cancer. His sons — Steven, Rodney and Trevor — are now co-owners of the company. Steven Ward talked with Archery Business about Vortex Broadheads for this issue’s Spotlight column.

AB: Thank you for taking the time to talk with Archery Business for this column. Can you tell us a little bit about your company’s history and what sparked its founding back in 1988?

SW: In 1986, my father, Dennis, was on an archery elk hunt in northern Arizona. He snuck into range of a mature cow and made a bad shot, hitting her too far back. I recall him telling me the story and how he felt so bad watching that cow for hours in its bed still alive. At that time, he decided to invent a broadhead that would cut almost 3 inches wide. He knew the bigger the hole, the faster an animal would expire. While I watched my father make the first Vortex broadhead in our garage, I remember to this day the words he said: “Son, this broadhead will turn a poor shot into a marginal shot, a marginal shot into a good shot, and a good shot into a great shot.”

AB: How did your father come up with the name of the business? It's unique and distinctive.

SW: The original Vortex Broadheads blades were sharpened single bevel, so the broadhead spun like a vortex while passing through the animal.

AB: Almost 35 years is quite a run in the outdoors industry, especially during the last few years. How did the pandemic affect Vortex and its staff, and did you come out okay from it?

SW: The pandemic did not have much of an effect on our sales. We are a small company with a strong following. We have hunters who have been shooting Vortex Broadheads since the early 1990s.

AB: What advice would you give to small companies with a good product looking to grow financially and for a stable future?

SW: My advice is to take the risk, jump in head first and follow your passion. I personally believe with no risk comes no reward.

AB: What goes into the production of an effective, sturdy broadhead? Good steel? Machining? Is there any one thing that is a no-doubt must-have component in the process?

SW: Quality materials and machining are very important to a good, quality broadhead. Our blade material is second to none. Our ferrules are made of only the highest quality steel and aluminum. We also have some other methods of making our broadheads as strong as possible, but they are a trade secret.

AB: What is the company culture like at Vortex Broadheads?

SW: The company culture is family-driven. We all work as a team and do what's best for the business.

AB: You’ve stuck with, pretty much, the same broadheads and design over the years without branching into myriad others. It seems to be the epitome of the KISS method. Why has this worked for you?

SW: Our broadheads are of a simple design because they work, and as you said they follow the KISS method. Why fix what isn’t broken? The Vortex design guarantees complete deployment. The way the broadhead blade angles are designed guarantees deployment on all sizes of game animals, from as little as quail to as large as bison.

AB: What is your top-selling broadhead dealers should know about?

SW: Our top selling broadhead is the Vortex 100-grain 2.5-inch Orange broadhead.

AB: Over the years, interest in bowhunting has risen and fallen like the tides. What do you see right now for the future? Are we on a rising tide, at the crest, or something else?

SW: It is hard to say. Every year we see a rise in sales of our broadheads. I am not sure if that is because our broadheads are becoming more popular, especially since our resurgence in 2017, or if archery is becoming more popular.

AB: Dealers often hear customers say, "Why should I shoot expandable broadheads?" What advice would you give them to relate to their customers?

SW: Not all expandable broadheads are made the same. Some are rear-deploying and others front-deploying, Some are made with high-quality materials and others with sub-par materials. So to lump all mechanical broadheads in one group wouldn't make sense. I can tell you why hunters should shoot our heads! Vortex Broadheads have been around and tested since 1988. They are made of the highest quality materials and will never fail. Even if you were to weld the blades shut you would still have a 1-inch entry and exit wound. Vortex Broadheads are guaranteed to deploy, even on game as small as quail. Broadheads kill by making the animal hemorrhage. Vortex Broadheads offer cutting diameters from 2-inch to 3 1/8th inches, and the bigger the wound the faster the animal will expire. Fact!

AB: What are your company goals for 2023 and beyond?

SW: Our company goal is to keep the legacy of our father and mother alive along with the Vortex Broadheads name. We will be releasing a new design at the 2023 ATA Show in honor of our father. The new broadhead is a hybrid, all-steel 1.5-inch cutting diameter head. A portion of the sales of each pack will be donated to stomach cancer research.

AB: How does Vortex Broadheads support and work with its dealers?

SW: Vortex Broadheads has been successful by keeping everything simple and doing what works. No need to constantly change broadhead designs or try to innovate new technology. If you have a design that works, improve on that design instead of trying to reinvent the wheel. Vortex Broadheads truly appreciates our dealers. They are the ones getting our broadheads in the hands of the consumers.

AB: How can dealers get in touch with you if they’re interested in Vortex Broadheads?

SW: Any dealers interested in carrying our products can contact us at info@vortexbroadheads.com or by calling (520) 766-2500.