If you’ve ever watched an ultrasonic cleaning unit in action at the jewelry store, what’s going on isn’t always clear or easily detected. Your wedding ring or some other piece of jewelry goes into a small basket immersed in liquid and the machine hums a bit. Ripples are detectible on the surface. You know something’s happening but can’t see it.

Then, voila. The jewelry is sparkling. A wipe with a dry cloth, maybe a touchup under the polishing wheel, and the jewelry looks brand-new. Ultrasonic cleaning is like a facelift for metal parts, and this includes firearms you service in your store. Adding an ultrasonic cleaner to your shop could be a benefit for you and your customers.

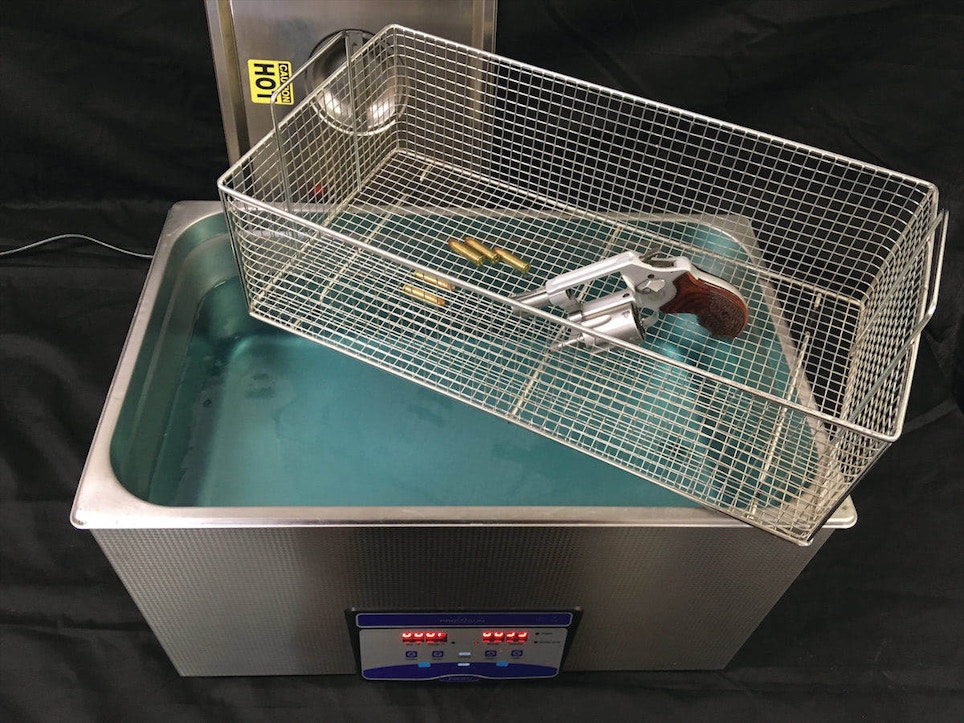

The same ultrasonic units used in a jewelry store or medical offices can clean everything from the tiniest screws and springs to rifle barrels better than you can with a rag, brush and spray. Guaranteed. You can prove it to customers, too, with an ultrasonic unit on your display counter to clean their pistols.

“The beauty of ultrasonic is it produces microscopic bubbles with incredible energy that attack a part (in the tank) from an infinite number of angles,” says Dan Kentch, founder of Pro Ultrasonics Inc. near Charlotte, North Carolina. “Cleaning a pistol, for example, we’re going to get into so many cracks and crevices and pores, into the lands and grooves in the barrel that you might miss with a brush, all those little corners and places you can’t get to, and it’s going to clean and lubricate those like never before. Ultrasonic is a safer cleaning product that is hands-free and cleans better.”

Kentch started Pro Ultrasonics in 2000 and today offers more than a dozen units along with custom builds for specialized products. His company has done work with major corporations such as Delta Airlines and Stewart-Haas Racing as well as others in the medical, manufacturing, aerospace/defense and machining industries. Kentch has helped tattoo artists and championship race car drivers. He doesn’t have a hardcore pitch because the ultrasonic cleaners pretty much tell the story once a product goes in dirty and comes out clean.

Range Test

At a Blue August PR gunwriter media event in 2019, Kentch had several Pro Ultrasonics tanks on display at the Clark County Shooting Complex. In one tank he had water with a bit of his Pro 100HD Ultrasonic Soap, a heavy-duty degreaser. Another tank held Lucas Oil Bore Solvent & Gun Cleaner, which removes lead, copper, carbon fouling, oil, powder and grime. During the couple days at the range shooting everything from small pistols to large AR rifles, he cleaned everything immersed in the tanks including spent brass that had been lying on the dusty Las Vegas desert around the range bays.

After a few minutes in the tank with the Pro 100HD soap, Kentch would put the basket with the parts into a tank of water for a rinse. Gun oil could be applied before reassembly. The Lucas Oil solvent and cleaner left a thin lubricant on the parts. A quick wipe and reassembly, and it was back to the range for more trigger time.

Kentch runs his tank fluids at about 140 degrees but heat isn’t necessary, he says. The tanks can be drained and fluid replaced as desired, thanks to special nozzles designed in the tanks. During the Las Vegas event we filtered the Lucas Oil solvent to remove the grit and grime and reused it. That helps save costs of buying solvents.

“One of our new designs is a three-chamber unit for a tabletop,” Kentch says. “Something like that is especially good for a busy gun shop or range if they offer cleaning as a service. They can have three going at the same time. Some of the busier places say they have a lot going on and don’t want to buy multiple tanks, so this three-tank unit was a good thing. Cleaning times are one to two minutes and you can process a lot of weapons or parts in a short amount of time, very safely.”

How Ultrasonic Works

Ultrasonic cleaning involves short, high-frequency sound waves that create cavitation bubbles in fluid. These bubbles collapse after striking something, creating a micro burst of pressure and heat that rises to the surface.

These sound waves are pounding through the fluid, bombarding anything in the tank. If you’ve watched an ultrasonic unit in action at the dentist or jeweler’s shop you maybe can see the fluttering waves on the surface. This constant agitation creating the microscopic bubbles helps remove dirt, grime, oils and other grit from the pores of metal, plastics, glass and rubber. Ultrasonic cleaning is not recommended for anything that has electronics or for porous materials and gems, such as pearls.

You cannot hand-clean a firearm with a rag, brush and solvents better than you can with an ultrasonic cleaning unit. It’s impossible because you’re unable to get a brush into the tiniest of crevices or pores. In just four or five minutes, an ultrasonic cleaner can handle items from tiny screws and springs to an AR-15 upper and barrel.

“We have had mechanics take apart engines or other parts for airline engines, motorcycles and dragsters, clean the parts and then rebuild the engines,” Kentch says. “They see it as a huge benefit to their preparation. A gun store or range owner could do the same, and it adds value to the business because it’s a service you can offer to customers.”

Selling the Service

Kentch says years ago at trade shows he would offer to clean jewelry and chat with the men or women while they waited. After a few minutes he returned the items, had a happy new friend and that often turned into sales. He believes firearms retailers can do the same.

“You have someone who comes into the range or store and they’re carrying, so you offer to clean it for them. Obviously you make sure it’s unloaded and then you can field strip it, clean it, give it a nice oil bath, wipe it, reassemble and return it. While that’s going on they can be looking around or talking with you about a new gun or accessory. Is anyone else doing that in your area? If not, that’s something different you can promote as a special service to customers.”

Kentch has ultrasonic units small enough to handle a pistol and 48-inch models big enough for rifle barrels and actions. He says they all have “the same power and cleaning times, so it’s just a matter of what you want to put in there.” He also makes larger units for industrial uses. With the rise in reloading, too, he says ultrasonic units clean new or previously used brass better than tumblers with mixed media.

“If nothing else, it’s an extra bonus for your business. It’s safe, simple, clean and a benefit for you and the customer.”