Some things are a given. But some things are only a given until some interested — and often very intelligent — person starts thinking out of the box. Among the latter, there is the long-time “fact” that cartridge cases must be made of some kind of metal (most often brass, but steel and even aluminum are sometimes used).

To see living proof of how that is no longer true, look no further than True Velocity Ammunition.

Much Ado About Ammo

During testimony in front of the U.S. House Armed Services Committee, Dr. Bruce Jette, assistant secretary of the Army for acquisition, logistics and technology, mentioned the shortfalls of current ammunition manufacturing logistics in the United States and provided a blueprint for modernization.

“We have been reticent to bring our production facilities into the 21st century,” Dr. Jette said. “But we are at an inflection point, knowing that technology offers true modernization pathways that can significantly improve both safety and transform the production capability.”

Enter True Velocity, headquartered in Garland, Texas, not far from the Dallas metroplex. That company has what its leaders believe is the answer to this important problem.

“We are uniquely positioned to enhance the armed forces’ capabilities through manufacturing modernization and enabling logistical efficiencies,” says Chris Tedford, True Velocity president. “At True Velocity, we obsess over quality control and want to provide our country’s leaders with solutions that reinvent ammunition production, industrial supply chains, quality and distribution.”

If you think that sounds like a tall order, you’d be correct. What True Velocity came up with is something few expected — ammunition made using a polymer composite case rather than a brass case.

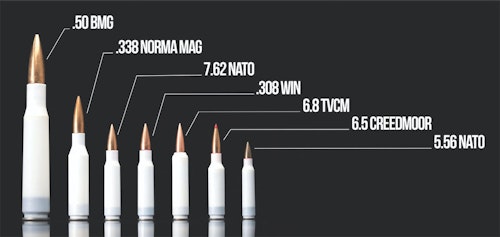

In May 2020, True Velocity delivered more than 170,000 rounds of its 6.8mm TVCM lightweight ammunition to the U.S. Army as part of the Next Generation Squad Weapon (NGSW) program.

“As a team, True Velocity is excited and proud to have delivered this significant order of next-generation ammunition to the Army in full and on time,” Tedford said at the time. “Our 6.8 TVCM composite-cased cartridge is capable of unprecedented ballistic performance, while simultaneously exceeding the Army’s expectations in terms of weight reduction.”

Now, True Velocity has the capacity to produce as many as 600 million rounds of polymer-case ammo per year.

Taking Form

For many seeing the polymer cases for the first time, it seems unbelievable that they could hold up to the pressure and temperature involved in firing a high-speed projectile from a rifle.

In fact, these new cases have many advantages over typical brass. First, of course, is the weight, as the polymer cases make a loaded round about 30% lighter than a similar round using a brass case. If you’re just carrying a 20-round box of ammo in your backpack up to your deer stand, this might not seem like a big deal. But if you’re a soldier lugging a heavy load in hostile territory, the difference means you can haul the same amount of ammo with 30% less weight, or haul 30% more ammo without increasing your ammo load.

The way the cases are formed presents another advantage. The forming process begins with a steel-cased head that’s over-molded with polymer. The case neck and shoulder are molded separately, then fused to the lower part of the case. This allows for interior case dimensions that are far more precise than what is possible with brass — 10 times more precise, according to the company.

That means ammo can be loaded with the perfect case capacity for the intended load — no more compressing powder because a case is a little too full or empty case space for loads that don’t require powder to fill a case all the way up. The result, according to the company, is better ignition, resulting in more consistent velocity.

Another major advantage of the polymer case stems from the very nature of polymers. Because polymers don’t hold heat, these cases help maintain much lower temperatures inside the chamber than cartridges loaded in metallic cases. That helps avoid excessive heat problems that can occur in high-power rifles fired rapidly for an extended time.

The last benefit I found was that all the guys at deer camp are going to be interested and they’ll all want to try a few rounds through their rifle. In the long run, word will get out and people will be asking you about this ammo.

Gearing Up

When I asked the company last fall what ammunition they were making for deer hunting, they responded by sending me a couple of boxes of their .308 Win. ammo topped with the 165-grain Nosler Accubond bullet. While not my favorite deer bullet, the Accubond has accounted for a lot of whitetails in its time.

One roadblock remained — I didn’t have a rifle chambered in .308. I know that might be sacrilegious in many parts of the country, and I’ve kicked myself a time or two for never getting one. I remedied that with a quick call to Savage Arms. The good folks there agreed to send me one of their new straight-pull bolt guns that I had been wanting to test since they were introduced the previous year.

The Impulse Big Game features a straight-pull bolt — rare in U.S.-made rifles — with a hazel green Cerakote aluminum receiver and steel barrel, KUIU Verde 2.0 Camo AccuStock with AccuFit adjustable length-of-pull and comb height, and the fantastic adjustable AccuTrigger, for which Savage is famous. The gun also features a carbon steel, fluted barrel and is fed by a flush-fit detachable box magazine.

The Impulse Big Game is available chambered in 6.5 Creedmoor, .243 Win., .30-06, .300 Win. Mag., .300 WSM and, of course, .308. In addition to the Big Game model, Savage offers the Impulse in three other models — Hog Hunter, Predator and Elite Precision.

In The Field

As you’re all well aware, supply chain problems wreaked havoc during 2021, and my Savage rifle didn’t arrive before the opening of deer season in my home state of Oklahoma.

Thankfully, my best friend and hunting buddy has an awesome little Kimber mountain rifle chambered in .308, and he offered to let me use it on opening morning. He would use an old rifle that he had retired since getting the Kimber. I arrived at camp before sunset the day prior to the opener and immediately shot a tight, three-shot cloverleaf group only a half-inch from his scope’s point of aim, leaving no reason for any adjustments.

The next morning dawned bright and fair, and the deer were moving only sporadically. I sat with a chamber full of True Velocity but never saw a buck even approaching shooter dimensions. And yes, my buddy had a good one come by and killed it with his old rifle.

Later that day, one of the other hunters at camp finagled a handful of rounds from me and sighted them in through his rifle. That evening, he killed a nice 8-point with the True Velocity .308, dropping him in his tracks at about 100 yards.

The next morning my buddy with the Kimber used the True Velocity to kill two large feral hogs, neither one traveling far after taking the Accubond through the boiler room. Everyone was impressed with the ammo but I never got a chance to put it to the test.

The shipping gods finally shined down on me when the Savage arrived later in December. Looking at my calendar, I realized the state’s late antlerless hunt opened the next day and quickly scheduled a trip.

Arriving at camp late morning of the opener, I got the Savage sighted in and put several rounds through it with great accuracy. That evening I killed two large does — one at about 100 yards, the other around 140. One dropped in its tracks, while the other traveled 30 or 40 yards before succumbing.

Over the two deer seasons, I had loaded and unloaded the True Velocity ammo in and out of a number of different rifles over and over, and they were no worse for wear after all that. In the end, the final score in western Oklahoma was True Velocity – 5, Deer and Hogs – 0. While not a real scientific test, it sure convinced me these bullets are something special.

Making Fans

Brass-cased ammunition is far from dead but I believe the extraordinary technology harnessed by True Velocity is here to stay and we’ll see more and more offerings from the company as time goes on.

Just remember: First impressions aren’t always the correct impressions. Seeing your first round will likely make you a skeptic. Shooting your first round will likely make you a fan and follower.